Demand forecasting in the supply chain is crucial for optimizing inventory levels and ensuring efficient resource allocation.

Did you know Mckinsey Digital suggests that AI-driven forecasting can cut errors by 30% to 50% in supply chains, resulting in a 65% decrease in lost sales from inventory shortages It also reduces warehousing expenses by 10 to 40%. The expected impact of AI on the supply chain is estimated at $1.2T to $2T in cost savings in manufacturing and planning.

This blog covers the key areas of demand forecasting in supply chain management with a focus on GenAI and LLMs. Read till the end to find real-time customer stories on optimizing supply chain with advanced analytics and GenAI solutions

Table of Contents

What is Demand Forecasting in the Supply Chain?

Demand forecasting predicts what goods and materials will be needed to keep businesses profitable. Without accurate forecasting, companies risk having too much surplus or missing out on opportunities because they can’t anticipate what customers want.

For example, you head the supply chain unit in a chip manufacturing company. If you can’t forecast chip requirements for the coming 3 months, your production unit can’t even have a manufacturing plan for the three months. It will affect your production line and overall efficiency.

Why is Demand Forecasting Important in Supply Chain Management?

Demand forecasting in supply chain management involves predicting demand, supply, and pricing by analyzing past patterns and competitor data. It’s crucial for scheduling, planning, and meeting customer needs. The following key points reveal why demand forecasting is important in supply chain management:

Demand forecasting in the supply chain helps enhance scheduling by analyzing past and present demands.

Forecasting in supply chain management is crucial for anticipating seasonal demand fluctuations, as well as planning promotional activities and product launches. Accurate predictions based on data reduce guesswork and enhance planning efficiency.

Demand forecasting enables businesses to predict product demand even in highly specific scenarios. Though complete accuracy is impossible, relying on data patterns and informed decisions based on historical and present data can significantly improve prediction accuracy.

Predicting customer demand ensures timely order fulfillment, enhancing customer satisfaction and fostering trust between customers and suppliers.

Forecasting eliminates the need for safety stock by accurately predicting demand fluctuations, freeing up storage space, and saving time and resources.

Predicting product demand enables supply chain managers to optimize shipping operations by ensuring adequate staffing levels. This prevents order fulfillment delays due to insufficient workers or excessive labor costs.

Price forecasting empowers companies by enabling them to predict and manage the impact of price changes on different areas of the supply chain, facilitating informed decision-making and effective management of pricing strategies.

Types of Demand Forecasting

There are six types of demand forecasting:

Passive Demand Forecasting

It relies on past sales data to predict future trends, making it suitable for businesses with stable sales patterns. This method assumes consistency in sales from year to year and is ideal for businesses prioritizing stability over growth. It requires no statistical methods or economic trend analysis.

Active Demand Forecasting

This integrates market research, marketing strategies, and expansion plans to inform decision-making, making it beneficial for businesses in growth phases or startups. It considers external factors such as economic outlook and market sector growth projections, which are especially relevant for ventures lacking historical data.

Short-Term Projections

It focuses on the next three to twelve months, facilitating just-in-time supply chain management and enabling rapid response to changing customer demands, which is particularly valuable for businesses with frequently changing product lineups.

Long-Term Projections

Long-term forecasting projects one to four years into the future, shaping business growth trajectories and aiding in strategic planning for marketing, capital investments, and supply chain operations. It combines sales data and market research with aspirational goals.

External Macro Forecasting

This considers broader economic trends and their impact on business goals, providing direction for meeting objectives and addressing factors like raw material availability affecting the supply chain.

Internal Business Forecasting

It assesses internal capacity constraints and operational factors influencing growth potential. It identifies limitations and opportunities within the organization, considering financing, profit margins, supply chain efficiency, and workforce capacity to guide realistic projections and capacity-building efforts.

How to Forecast Supply Chain Demand Accurately?

Accurately forecasting supply chain demand involves several key steps:

- Data Collection: Gather historical sales data, market trends, customer preferences, and any other relevant information.

- Data Analysis: Use statistical techniques, machine learning algorithms, and predictive analytics to analyze the data and identify patterns or trends.

- Demand Modeling: Develop demand models based on the analysis to predict future demand. Consider factors such as seasonality, promotions, and external influences.

- Collaboration: Collaborate closely with stakeholders across the supply chain, including sales, marketing, and operations teams, to gather insights and validate forecasts.

- Continuous Improvement: Continuously monitor and refine the forecasting process based on actual demand data and feedback from stakeholders. Incorporate new data sources and adjust models as needed to improve accuracy over time.

Role of Data Analytics in Demand Forecasting

Supply chain managers utilize data analytics to analyze customer behavior, recognize patterns, and predict future demand. By leveraging predictive analytics, companies can synchronize their production and distribution processes with expected demand, reducing lead times and lowering inventory carrying costs.

Data analytics also enhances logistics and distribution networks by offering insights into optimizing transportation routes, selecting cost-effective carriers, and minimizing shipping delays. This streamlining of logistics processes results in reduced operational expenses and improved customer satisfaction.

Furthermore, implementing data analytics in supply chain decision-making enhances operational efficiency by identifying bottlenecks and optimizing workflows, while real-time data insights enable agile decision-making to respond promptly to market changes.

Note: Find out how to solve supply chain bottlenecks to optimize workflows

Additionally, data analytics provides unprecedented visibility into supply chain operations, enabling the monitoring and analyzing every step, from sourcing raw materials to tracking shipments. This transparency aids in identifying inefficiencies, maintaining quality standards, and fostering stronger relationships with suppliers and customers.

Moreover, data analytics helps mitigate risks and disruptions by identifying potential risks and developing contingency plans. By modeling different scenarios, businesses can prepare for uncertainties and minimize the impact of disruptions on their supply chain.

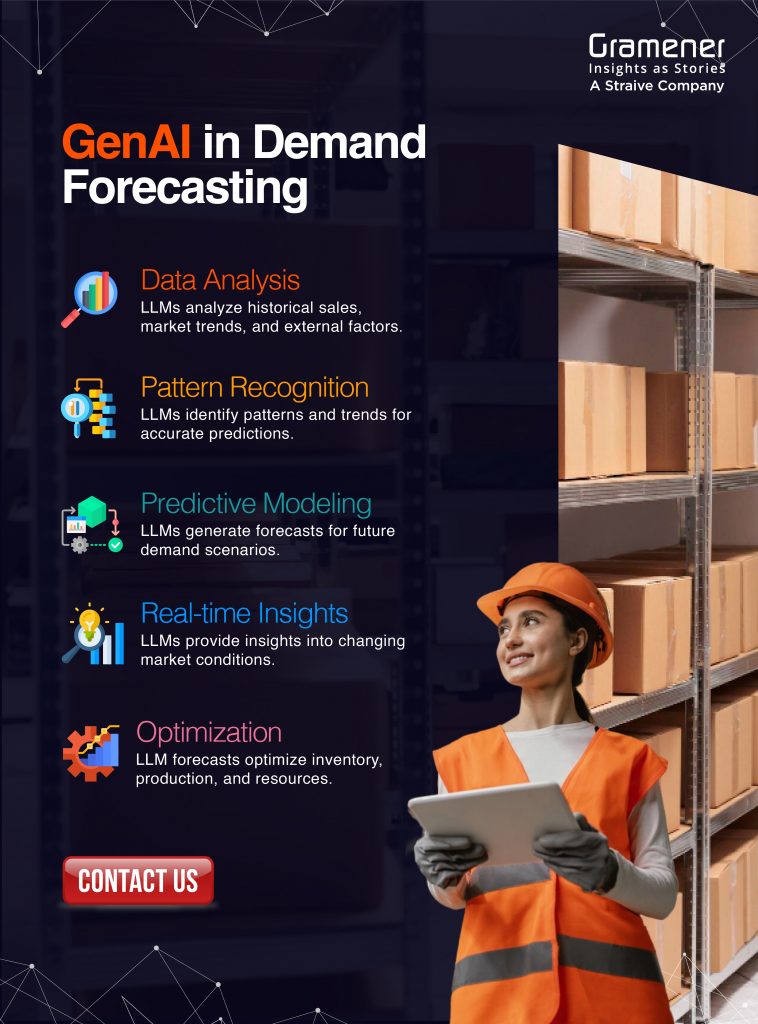

Role of GenAI in Demand Forecasting

GenAI’s LLMs (Large Language Models) play a crucial role in demand forecasting in supply chain management by leveraging their ability to process and analyze vast amounts of data. Here’s how LLMs contribute:

- Data Analysis: LLMs excel in analyzing historical sales data, market trends, and various external factors influencing demand, such as economic indicators and seasonality patterns.

- Pattern Recognition: LLMs are proficient at identifying patterns and trends within the data, allowing for more accurate predictions of future demand based on past and present information.

- Predictive Modeling: Using advanced predictive modeling techniques, LLMs can generate forecasts for future demand scenarios, helping supply chain managers anticipate fluctuations and adjust their strategies accordingly.

- Real-time Insights: LLMs provide real-time insights into changing market conditions, enabling companies to make agile decisions and respond promptly to shifts in demand.

- Optimization: By integrating LLM-generated forecasts into supply chain planning processes, companies can optimize inventory levels, production schedules, and resource allocation, improving operational efficiency and cost savings.

Benefits of Demand Forecasting

- Streamlined Inventory Management: Precise demand forecasting is essential for optimizing inventory, minimizing the chance of lost sales from stockouts or surplus resources. Diverse forecasting techniques, including surveys and statistical methods, are instrumental in recognizing purchasing trends, facilitating meticulous stock analysis, and achieving optimal inventory control.

- Enhanced Production Planning: Leveraging data-driven insights from historical sales and market trends enables businesses to efficiently schedule production cycles, thereby reducing the occurrence of stockouts or excess production. Precise demand forecasting ensures timely order fulfillment, enhancing operational efficiency.

- Efficient Resource Allocation: Utilizing demand forecasting facilitates efficient resource allocation, optimizing the utilization of personnel, equipment, and materials. This prevents unnecessary expenditures and resource depletion, thereby enhancing overall efficiency and cost-effectiveness.

- Sustainability Improvement: Precise predictions enable the maintenance of optimal inventory levels, curbing resource waste and bolstering both economic and environmental sustainability.

- Increased Sales and Revenue: Insights from demand forecasting guide decisions across production, inventory, pricing, and marketing strategies, resulting in heightened revenue and expanded market opportunities. Businesses can tailor production schedules to meet client demands and devise impactful sales tactics based on consumer behavior.

- Strategic Pricing: Demand forecasting aids in constructing pricing strategies through a comprehensive analysis of consumer behavior and market trends. The goal is to maximize profitability while managing risks. Refining pricing points using historical data and current market trends enhances revenue generation.

Empowering Companies with Demand Forecasting Solutions

Through innovative methodologies, Gramener enables USCS to anticipate demand spikes with precision, empowering them to optimize inventory management and streamline operations efficiently.

With this remarkable accuracy, USCS gains a competitive edge in the dynamic supply chain landscape, ensuring timely deliveries, minimizing stockouts, and maximizing customer satisfaction.

Our partnership with USCS exemplifies the transformative impact of data-driven strategies, driving growth and success in the evolving business landscape.

Gramener for Accurate Demand Forecasting

We enhances demand forecasting in supply chain management by leveraging the power of GenAI and LLMs.

Through GenAI’s advanced algorithms and machine learning techniques, coupled with LLMs’ natural language processing capabilities, we can analyze vast datasets, including sales history, market trends, and external factors.

This enables precise prediction of future demand scenarios, allowing supply chain managers to anticipate fluctuations and optimize inventory levels, production schedules, and resource allocation.

By leveraging GenAI and LLMs, Gramener empowers businesses to make data-driven decisions, enhance operational efficiency, reduce costs, and stay ahead in today’s complicated market landscape.

Want to know more?