According to a study, 42% of supply chain companies reported having accelerated their digital supply chain transformation plans because of the pandemic. 90% of the participants had already started their digital journey.

Supply chain businesses that have already embraced technology face minimal interruptions. Supply chain transformation has helped them steer ahead of their competitors. It thus brings us to the pertinent question of digital transformation in supply chains.

This article looks at the importance of supply chain transformation and the cost benefits.

Table of Contents

What is Supply Chain Transformation?

The digital transformation of a supply chain involves leveraging technology to improve performance. Supply Chain Digital Transformation helps businesses revamp their processes and practices.

Transforming supply chains can be multi-faceted but involves two primary areas of operation. The first is implementing transformation management practices, and the next is making digital investments.

Transformation management is about using and implementing digital assets. Digital investment is about adopting technology tools that will help you fuel transformation. Even if businesses have put effort into improving their supply chains, not many have leveraged technology to its fullest.

According to a McKinsey study, Supply Chain Transformation was the lowest among all the businesses examined. The same research also found that companies with an aggressive focus on digital transformation expected to grow their revenue by 3.2%.

Learn the Basics: What is Supply Chain Analytics and learn how it can help with the digital transformation of the supply chain.

How Can Data and Technology Help in Supply Chain Transformation?

Digital transformation of the supply chain is leading to exciting developments. Businesses and their customers can interact in newer ways with several benefits. It is fast blurring the lines between the physical and digital worlds to reduce constraints and improve efficiency. Here are a few examples of how that is happening:

Transportation Route Optimization with Data

How can a vendor plan the route to pick up raw material from suppliers efficiently? Or how can a supplier identify better routes to ensure on-time delivery?

Getting a data visualization of your supply chain routes to identify the best routes can help you improve cost and time effectiveness.

Businesses can leverage route and vehicle data to identify optimized paths. Some analysis parameters include vehicles’ start and finish times and understanding less busy times of day on roads.

Altering these variables helps identify optimized transportation routes. It helps find the shortest and most economical paths, saving operational costs.

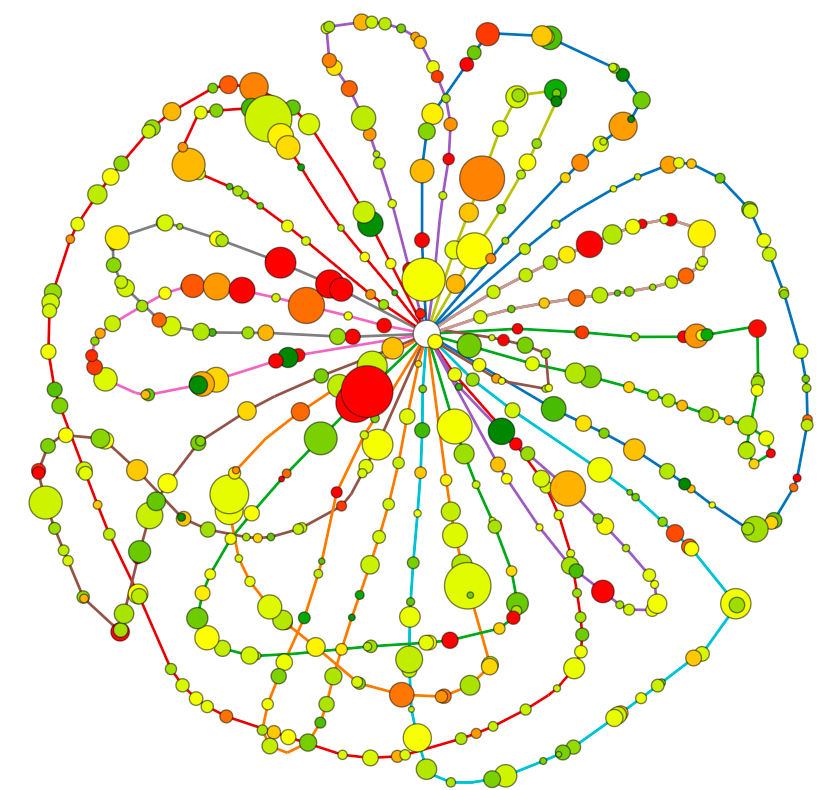

Below is the (anonymized) supplier network for a plant. Each circle represents a supplier. The size of the circle represents the volume of supplies purchased from that supplier. The larger the circle, the larger the purchases. The color of the circle represents the price at which it was purchased. Red indicates a high price, yellow is neutral, and green is low.

Each sequence of lines represents a supply route along which trucks are sent to pick up supplies. The length of the lines is approximately the distance between two suppliers.

This makes it easy to spot which routes are unprofitable, which distant suppliers are not worth traveling to, and which ones to negotiate the most with.

Truck Appointment Data

There is a grave need for automation in scheduling truck appointments for large supply chain organizations.

The major inevitable challenges that the scheduling department faces are:

- Idle trucks, especially in cold chain companies, have to stay on. More time in appointment scheduling keep the truck idle which leads to enormous fuel consumption. Hence, the cost is increased.

- Late truck appointments lead to late departures, which results in late deliveries. Companies like Walmart, that are dependent on supply chain vendors to keep their inventories fresh may charge hefty fines for late deliveries.

- Warehouse incompetency to hold more goods due to a pipeline of drivers waiting to unload and pickup can result in a space crunch for storage.

Truck appointment APIs help connect your transport management system with truck terminals. The integration helps you manage appointments at terminals seamlessly. You can use real-time data to plan trips better and avoid time wastage. Automated systems also overcome errors and inefficiencies resulting from manual work.

Gramener collaborated with the United States Cold Storage company to develop an AI-driven Intelligent Appointment Scheduler. This helped the warehouse management team automate pick up and unload timings, saving costs on fuels and resulting in faster deliveries.

The solution also helped the U.S. Cold Storage automate appointment scheduling in 26 warehouses and save over USD 300K in cost.

Delivery Pickup

Scheduling deliveries and pickups are a seamless activity with related online tools. You can access them 24×7 to schedule shipments. All you need are the basic details regarding the consignment to ensure proper delivery.

What Problems Can Supply Chain Transformation Solve?

Supply Chain Transformation brings along a range of benefits. Let us look at some critical problems that it can solve for your business:

Cost Reduction in Operations

Research suggests digitizing supply chains has a wide-ranging impact on reducing operational costs. It can save up to 20% on procurement costs and up to 50% on supply chain-related investments. Besides cost-saving benefits, there is also a possibility of a revenue increase of almost 10%.

These statistics hold true for businesses that want to reduce operational costs and increase revenue. Newer technologies and management practices also deliver a competitive advantage to organizations looking to improve customer satisfaction.

Route Optimization

A Digital Supply Chain helps to reduce the planning time while saving on labor and fuel costs. It identifies better routes and allows for a fair workload allocation across drivers due to an improved planning function, thereby enhancing employee satisfaction. Real-time updates to stakeholders and better time management, also keep customer satisfaction levels higher.

Automated Appointment Scheduling

Supply Chain Transformation helps carrier businesses streamline their scheduling arrangement. They eliminate issues like inaccurate appointments that impact revenue streams. The benefits of digitization also extend to transporting goods, taking the most optimized delivery route.

Delay in Deliveries

Delivery delays can be due to several reasons beyond your control. An optimized supply chain helps overcome this problem by streamlining activities. Businesses can also reduce delivery difficulties with drones within the warehouse environment and while shipping the product to the customer.

Optimized Warehouse & Inventory Management

Artificial intelligence in supply chains helps optimize warehouse and inventory operations. When you enable systematic inventory management, it helps improve efficiency. You can also study workplace safety data to minimize risks. Accelerated warehouse procedures through Supply Chain Transformation help overcome operational costs and increase efficiency.

The Process to Achieve Supply Chain Transformation

Digitizing your supply chains helps you streamline and optimize operational activities. Here are a few steps involved in the process that you need to consider:

Developing a Long-Term Vision of Supply Chain Business Goals

It is critical to understand and analyze the long-term goals on which your targets will rely. You can conduct internal surveys to identify the need for automation, reporting, and data and analytics in your Digital Supply Chain. The supply chain data findings will help you choose the appropriate technology and define strategies for implementation.

Hiring Digitally Sound People for Core Supply Chain Functions

Getting the desired results will only be possible when you have a skilled workforce. More than education, it is critical to consider what digital skills your future employees possess. Their digital expertise will help you fast-forward your implementation plans for optimizing the supply chains.

Focusing on the Correct Data and Technology

Data-driven transformation in the supply chain will help you revamp your business. It will also help you prepare for disruptions based on predictive models. Leveraging technology holistically across the organization is essential instead of using it piecemeal.

Strategic Data-Driven Decisions Aligning with the Above Three Steps

When you identify your short and long-term goals, hire the best resources, and choose your technology partners, it is time to improve your decision-making process. Data-driven decisions will help you eliminate the guesswork that can often prove costly.

Ensure that your goals are realistic for everyone to achieve. Keeping the right balance of difficulty and achievability will help everyone stay on course to accomplish them. Technology is another crucial aspect you need to consider. It can make or break your implementation process.

Gramener’s Data Advisory Offerings for Supply Chain

At Gramener we have a consulting wing that specifically helps our clients build data science roadmaps and accelerate their digital transformation.

Our data advisory consulting has helped multiple clients from the Supply chain, Pharmaceutical, and ESG sectors to impart data literacy and data-driven culture across their organizations.

Some Vital Achievements of Gramener’s Data Advisory Team

With a four-pronged approach that includes a robust Data and Analytics strategy, a comprehensive roadmap, value realization & data-driven transformation, Gramener has helped global supply chain leaders achieve up to 2.8% savings in manufacturing costs, 16% improvement in warehouse dwell time & $6 Mn savings from improved production yield & less wastage.

US Cold Storage, one of the leading warehousing & transportation service providers in the US, used our data & analytics solution to improve their warehouse efficiency by up to 16%.

We helped the technology subsidiary of a Fortune 500 company become digital & data-driven by identifying 70+ use cases impacting a potential top line of up to $200 Mn.

We also helped deliver a Data and Analytics roadmap to a mattress manufacturing major that improved its monthly production yield by more than 3%.

Bottomline

Considering recent global events, Supply Chain Transformation has become more critical than ever. Disruptions have become common, emphasizing the need for the increased digital transformation of supply chains. Technology has a lot to contribute to this segment, bringing in wide-ranging benefits for your business.

One of the visible advantages is a well-optimized supply chain and inventory management. When you streamline these activities, the other benefits like cost reduction follow. Reducing operational costs can have a direct impact on your bottom line. It will ultimately help you increase your revenue and achieve your goals.

Contact us for custom built low code data and AI solutions for your business challenges and check out supply chain AI solutions built for our clients, including Fortune 500 companies. Book a free demo right now.