The global food industry faces significant losses daily due to the spoilage of perishable goods. Fruits spoil in storage, vegetables get damaged during transport, and temperature-sensitive products like dairy fail to meet freshness standards due to poor handling. In addition to denting revenue, these inefficiencies increase food waste worldwide and aggravate environmental challenges.

Enter Computer Vision (CV), a technology that enables businesses to tackle these challenges head-on. CV completely changes how perishable goods are managed by automating quality checks, detecting spoilage early, and optimizing cold chain processes. Read on!

Read our blog to learn how computer vision can help you detect defects in packaging.

Table of Contents

The Challenges of Perishable Goods Management

Managing perishables effectively requires addressing several recurring challenges:

- Short Shelf Life: Many perishable goods, such as fresh produce and dairy, have a limited time frame for transportation, storage, and consumption.

- Manual Quality Inspections: Human inspections are inconsistent and miss subtle signs of damage, decay, or contamination.

- Variable Storage Conditions: It’s crucial to maintain ideal humidity, temperature, and other environmental conditions, but doing so might be difficult.

- Supply Chain Delays: Inadequate visibility across the supply chain often delays spoilage detection, leading to wasted inventory.

According to a U.N. report, globally, around 13.2% of food produced is lost between harvest and retail, while an estimated 19% of total global food production is wasted in households, food service, and retail.

How Computer Vision Addresses These Issues?

By combining advanced imaging systems, AI algorithms, and real-time data processing, computer vision addresses the challenges of perishable goods management. Its capabilities include:

- Automated Quality Inspections: CV technology analyzes visual cues such as color, texture, and shape to identify defective or damaged goods.

- Real-Time Spoilage Detection: AI-powered cameras monitor storage spaces for mold, discoloration, or degradation indications.

- Inventory Monitoring: Real-time stock level tracking by CV minimizes manual counting and ensures timely replenishment.

- Cold Chain Optimization: By integrating with IoT sensors, CV ensures the environment stays within acceptable bounds.

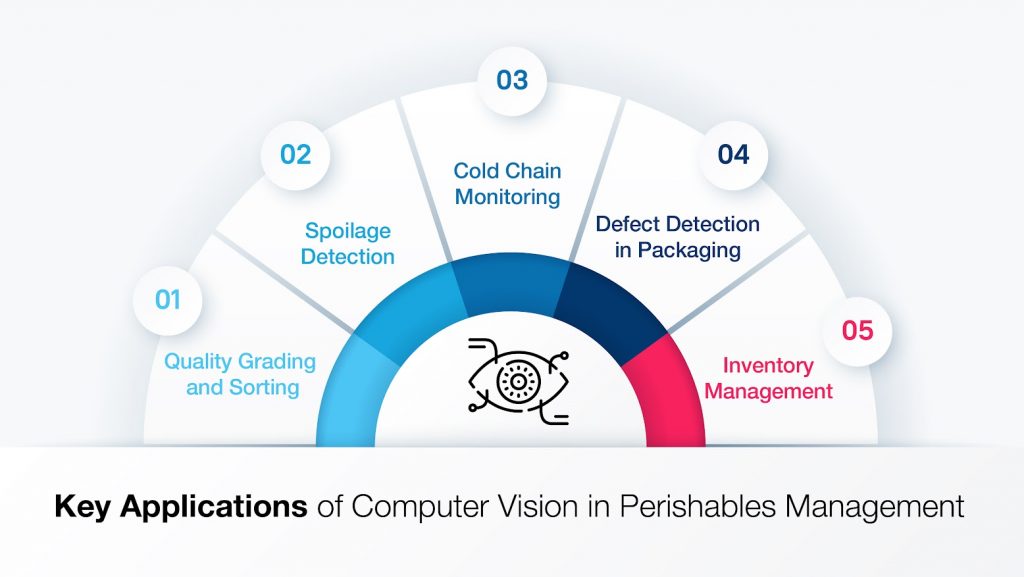

Key Applications of Computer Vision in Perishables Management

Computer vision automates the grading process for perishables, ensuring products meet consistent quality standards. CV systems assign product grades based on size, shape, and color.

- Spoilage Detection

Early spoiling detection reduces the chance of contaminated products entering the supply chain and avoids waste. CV systems use AI to detect visual signs of decay, such as discoloration, bruises, or mold, alerting operators for timely action.

- Cold Chain Monitoring

Maintaining optimal storage conditions is critical for preserving perishable goods. CV systems combined with IoT sensors track temperature and humidity levels in storage units and trigger alerts when deviations occur.

- Defect Detection in Packaging

Damaged packaging might jeopardize the quality and safety of perishable commodities. CV systems inspect the packaging for tears, leaks, or deformities and flag defective units for removal.

- Inventory Management

Automating inventory tracking helps CV reduce over- or understocking and ensures quick restocking. Cameras monitor inventory levels in real-time and update warehouse management systems.

| Read our blog to learn more about computer vision’s benefits and use cases in healthcare. |

Implementing Computer Vision

In order to adopt computer vision successfully, businesses should follow a structured approach, such as:

- Install Smart Hardware: Installing high-resolution cameras and IoT sensors tailored to specific needs.

- Leverage Advanced Algorithms: Deploying trained CV solutions for product type ensures accurate defect detection and spoilage alerts.

- Integrate with Existing Systems: Ensuring compatibility with ERP and warehouse management systems helps with seamless data exchange across operations.

Overcoming Challenges in Adoption

There are challenges in implementing CV in perishable commodities management, but these can be successfully overcome by following the below methods:

- Data Quality: Obstacles or inadequate lighting can reduce CV systems’ accuracy. For best results, ensure adequate lighting and calibrate the cameras regularly.

- Integration with Legacy Systems: Modern CV platforms may be incompatible with older systems. This gap can be filled by middleware or cloud-based integration solutions.

- Cost Concerns: While upfront costs may seem high, starting with scalable CV solutions can help small businesses minimize investment risks.

- Employee Resistance: Adoption can be facilitated by teaching employees how to use CV systems and emphasizing the advantages of their workflows.

How Gramener Can Help

Gramener delivers innovative solutions backed by AI and computer vision to help businesses overcome challenges in managing perishable goods. Our expertise is optimizing cold chain logistics, automating quality checks, and enabling real-time inventory tracking. By seamlessly integrating these technologies with IoT and data analytics, we help businesses maintain optimal storage conditions, enhance supply chain visibility, and reduce perishable goods waste.

Conclusion

Computer vision is a tool and a transformative force in perishable goods management. By automating quality checks, reducing spoilage, and streamlining supply chains, CV empowers businesses to deliver fresher products efficiently and sustainably.

Partnering with Gramener, a Straive company, can help you unlock the full potential of computer vision and ensure measurable improvements across your operations. Contact us today to learn more and start your journey toward smarter perishable goods management.