Why supply chain sustainability is such a buzzword amongst multiple corporate giants? Traditionally, Environmental, Social & Governance (ESG) issues have been low on the priority list of investors. However, an ever-expanding portfolio has forced the hands of pension funds & institutional investors who are eager to explore new frontiers without compromising their carbon footprint.

In 2006, 63 investment companies, including service providers, asset managers & asset owners, with assets under management (AUM) worth $6.5 Trillion, signed on to incorporate ESG considerations while making investment decisions, under the UN-backed Principles for Responsible Investment (PRI).

This number grew to 1,715 by Apr 2018 & represented $81.7 Tn in AUM.

Unfortunately, market forces and even encouraging supply chain sustainability statistics will not be able to solve the problems of climate change. Thankfully, many governments have taken the lead, setting targets & enacting laws to achieve net-zero carbon emissions by pre-determined dates.

US & China, the two biggest emitters in the world, have committed to becoming carbon neutral by 2050 & 2060, respectively.

By 2030, the EU Green Deal & Climate Law has pledged to cut 1990-level emissions by 55%, reaching climate neutrality by 2050.

Table of Contents

What is a Supply Chain?

The complex network of suppliers & distributors that help a manufacturer reach its products to its end customers is called the supply chain. This network comprises resources, information, entities, people & miscellaneous activities.

The supply chain includes all the steps required to produce a good from scratch & deliver it to its end user. It helps companies reduce costs & stay competitive.

What is Supply Chain Management?

The efficient management of the flow of all goods, services & processes to convert raw materials into finished products is known as supply chain management. It comprises streamlining all those activities designed to increase value to customers & establish a competitive position in the marketplace.

What is a Sustainable Supply Chain?

Organizations with sustainable supply chains ensure that their internal processes & their business partners operate legally, ethically & responsibly. In a sustainable supply chain, the environment is protected, local laws are followed, & workers are compensated & treated fairly.

What is Sustainable Supply Chain Management?

The integration of financially & environmentally viable practices into the end-to-end supply chain lifecycle are known as sustainable supply chain management.

The stages of a complete supply chain lifecycle include product ideation & innovation, raw material assessment such as agricultural production or raw material extraction, goods manufacturing, packaging, transportation, storage & warehousing, distribution, purchase, return & disposal.

Efficient & sustainable supply chain management can help organizations reduce their carbon footprint. It can also help optimize operations, increasing profits & decreasing costs.

Why Sustainability in Supply Chain is Important?

A sustainable supply chain is not just good for the environment. It is also good for business. Since industries today are focused on their environmental responsibilities, a supply chain that is built on a sustainable platform can result in lucrative partnership opportunities.

Organizations that practice eco-awareness in their business operations enjoy the confidence of their customers & peers.

A sustainable supply chain is a win-win for most companies, saving money while improving productivity. Sustainable techniques & resources help businesses increase the efficiency of machinery, vehicles & buildings, leading to substantial cost savings.

Nike, the biggest shoe manufacturer in the world, changed the way they made some of their shoes. This resulted in a 0.25% increase in margins & reduced material use & labor costs by 20% & 50% respectively.

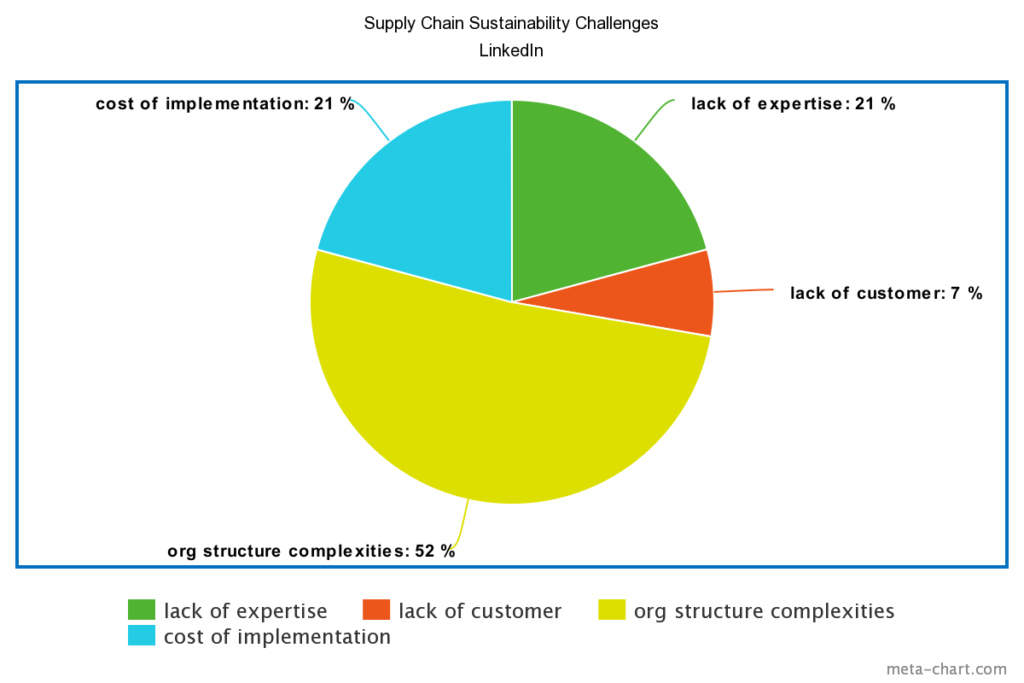

We did a survey on LinkedIn asking the audience the biggest challenge for any organization in adopting a sustainable supply chain.

- 21% of the business experts think lack of expertise is the biggest challenge to achieving a sustainable supply chain

- Only a few (7%) of the experts voted lack of customer interest as one of the challenges

- The biggest challenge for supply chain sustainability, quoted by leaders across the industry, is organization structure complexities. 52% of the audience voted it to be the biggest challenge

- 21% of industry leaders feel that cost of implementing sustainability in supply chains is so high that it becomes a barrier to achieving it

Examples of Sustainable Supply Chain Achieved by Brands

An Oxford Economics Study recently showcased how sustainable supply chain companies like Honeywell, EDF & Henkel have powered their initiatives by extending their supply chain transparency.

Henkel

For three decades, the German company that owns brands like Loctite & Schwarzkopf has published a sustainability report. Since 2005, the chemical & consumer products business has been stringently monitoring the environmental effects of its production processes.

By 2040, Henkel aims to achieve company-wide climate-positive results, going beyond carbon neutrality by removing atmospheric carbon dioxide.

In the last 15 years, the Laundry & Home Care business unit of Henkel has reduced its CO2-specific emissions by 65%. This is roughly equivalent to 3.5 million tons of greenhouse gas or the combined annual private household electricity emissions of cities like Vienna & Amsterdam.

The firm has achieved a 60% consumption rate of renewable electricity, on track to meet its target of running all facilities on renewable energy by 2030.

What started as a plan to monitor factory water usage & energy in real time led, over eight years, to the development of a digital platform responsible for deep supply chain analytics, transportation, customer support & end-to-end supply chain planning.

EDF

The biggest generator of zero-carbon power in Britain, EDF, is committed to attaining net-zero carbon emissions, in line with the UK government’s goal, by 2050. Its supply chain operations play a pivotal role in helping the organization meet its critical business targets & sustainability goals.

The firm tracks all indirect emissions occurring within its value chain, exploring the potential for impact reduction & innovation with its upper-tier suppliers.

The company has also implemented a mini-awareness campaign through a series of conference calls, learning opportunities & interventions. This helps to educate uninitiated suppliers less aware of specialized sustainability programs & complex regulations & aligning them with the net-zero ambitions of EDF.

Honeywell

By 2035, Honeywell, the global manufacturing giant, aims to achieve net-zero carbon emissions while transitioning into a software & industrial technologies provider from a product-oriented corporation. Supply chain digitization will help achieve these ambitious objectives.

Since 2004, Honeywell’s continuous supply chain transformation has helped reduce greenhouse gas emissions by 90%. It has also lowered costs.

To transform its operations based on data, Honeywell created a digital simulation of its whole business. This involved combining every piece of data across the organization, from an ERP system, a warehouse management system, or a sensor on a machine, into a massive data infrastructure.

This optimization has allowed Honeywell to increase its production yields, use fewer resources to make a single unit & reduce wastage.

The Three Salient Features of Supply Chain Sustainability

There are three key features of a sustainable supply chain – social, environmental & financial, similar to the Triple Bottom Line (TBL) method of accounting. Instead of solely focusing on profit & loss, TBL accounting measures the overall performance of a company based on its impact on:

People – social & human rights considerations, partner & customer treatment, & employees

Planet – environmental impact

Profit – long-term financial viability

Social

Companies must implement measurable goals to maximize their positive social impact. A 2015 study by Nielson Global found that 73% of the millennials surveyed will pay more for sustainable products, an increase from 50% in 2014.

Sustainable supply chain operators work with vendors who meet the health & safety standards & pursue fair labor practices. They also ensure that they do not inconvenience or pollute the communities where they operate.

Environmental

Supply chains that are concerned about their environmental impact, evaluate the amount of waste their delivery logistics & suppliers are generating & whether their manufacturing operations are helping to protect or pollute the environment.

They also monitor their overall carbon footprint, their energy & water usage rates & the use of recycled packaging & materials in their processes.

Sustainable supply chains appoint point persons to monitor & implement sustainable policies. These individuals oversee all sustainability projects & assess their progress regularly.

Financial

Companies that pursue sustainability can also be profitable at the same time. Process automation & digitization tools can help maximize profitability & lower costs.

Procurement teams can use technologies like Electronic Data Interchanges (EDIs) to go paperless, lowering operational costs while saving the environment. Enterprise Resource Planning (ERP) platforms & Automatic Identification & Data Capture (AIDC) can reduce waste in the supply chain & make procurement more efficient.

Incorporating a Supply Chain Code of Conduct that includes social & environmental elements can improve the working conditions of vendors across the supply chain. It can also enhance the brand image & reduce risks.

How Can Supply Chains Become Sustainable?

Sustainability initiatives can vary across supply chains, sometimes within the same industry. The following steps should broadly help organizations build sustainable supply chains.

Mapping the Supply Chain

The first step in a sustainable supply chain is to create a blueprint of the current operational process focusing on efficiency, waste reduction & resource management.

Companies sometimes invest in mapping software that allows them to highlight potential points for improved sustainability. It also provides them with a detailed picture of every aspect of their supply chain.

To successfully map supply chains to make them more sustainable, organizations must

- Trace every end product back to the raw material stage

- Identify suppliers at every step of the supply chain

- Monitor geopolitical risks

- Connect supplier assessments & audits

Leverage Technology to Identify Opportunities

Technology can help companies automate their code of conduct surveys & risk management processes for dozens or even hundreds of suppliers, facilitating compliance with high environmental & social standards.

Organizations can assess supplier risk using a supply chain information management system. Industry 4.0 applications like machine learning, AI & Big Data analytics can help identify the cheapest, fastest & most sustainable shipping routes.

It can also support collaboration between businesses, identifying opportunities for shared warehousing, trucking & shipping, significantly reducing carbon emissions.

Goals & Metrics Setting

Once the sustainability focus areas have been identified, the next step is to define the KPIs & the metrics. Sustainability benchmarking helps establish KRAs & KPIs by identifying areas for improvement.

A mechanism to monitor & track the progress of sustainability plans can be implemented once the benchmarks have been established. This can be done by measuring waste, profit, revenue, etc.

Monitoring the KPIs & KRAs regularly helps businesses identify the weak links within the supply chain. Frequent audits allow companies to track growth & gauge the effectiveness of their efforts against pre-defined metrics.

Learn, Unlearn & Re-Learn

As sustainability initiatives within the supply chain begin to bear fruit, managers will have to measure the results against the chosen metrics. The process outcomes may not always be as expected, leading to changes in approach, thought & perspective.

Sometimes, you may be required to rethink the whole design & take it back to the drawing board.

Technological Components of a Sustainable Supply Chain

To nurture the ability to trace & track shipments to any location & accomplish the goal of a sustainable & ethical supply chain, companies must leverage the right technology.

Machine Learning

Machine learning, coupled with good reporting & analytics, can continuously improve supply chain processes through small & iterative ways. Every change that enhances quality, speeds up delivery & reduces waste, helps improve sustainability incrementally.

Geospatial AI

In the absence of widespread availability of electric & other sustainable vehicle options, route optimization is one of the best ways to counter the harmful effects of distribution & transportation on the environment.

Geospatial AI can complement GPS devices to optimize local, national & international shipping routes. Advanced analytics can even account for congestion & other issues, updating routes in real time.

Predictive Analytics

Predictive analytics can help forecast where & when goods will arrive, efficiently coordinating shipments from multiple suppliers to multiple destinations. This, in turn, optimizes asset utilization, ensuring that no container goes empty.

By facilitating the transport of trailers & cargo efficiently, predictive analytics can also reduce the total amount of unit emission of greenhouse gases.

Learn more about the unique benefits of AI in supply chain and how AI/ML systems are utilizing data to generate useful insights.

Benefits of Supply chain sustainability

Like all ESG programs, building a sustainable supply chain requires commitment, time & resources. Capturing the benefits of a sustainable supply chain can help develop a robust business case & secure the buy-in for the project.

Lower Environmental Impact

This is the main objective of any supply chain sustainability project. These days, reducing the carbon footprint is a top priority for most companies. Building a sustainable supply chain can go a long way in accomplishing that goal.

Higher Business Efficiency & Lower Operating Costs

A 2016 survey found that efforts by leading US corporations to help suppliers reduce emissions resulted in cumulative savings of $12.4 Bn. A smaller carbon footprint increases efficiency & productivity. It also helps reduce overall costs.

Improved Reputation

ESG ratings & scores greatly influence investor & buyer decisions today. No company wants to jeopardize its ratings by risking its ESG credentials. In addition to environmental issues, factors like ethical sourcing & modern slavery fall under supply chain sustainability & affect the ESG credentials of an organization.

Failure to tackle supply chain sustainability issues can potentially damage your reputation. Proper oversight & supply chain management can help you avoid disrepute.

Opportunities to Forge New Partnerships

Companies that collaborate on supply chain projects demonstrably enjoy more benefits from the same. For example, operators in the footwear & clothing industry are collectively working towards a common goal of zero discharge of hazardous chemicals (ZDHC).

Good for Business

64% of consumers surveyed by Euromonitor believe sustainable product purchases can make a difference in the world. These consumers are interested to know who makes the products they purchase & how they are made. They also want to know about the environmental impact of transporting these goods.

Companies with sustainable supply chains can discover a lucrative consumer base by tapping this market.

Fosters Innovation

Organizations have to explain their purpose & corporate vision to their suppliers, get to know them & work closely with them to improve supply chain sustainability. As a result of gaining a clear view of the company goals, the suppliers can make invaluable suggestions to improve the processes, products & services.

Aids Employer Branding Efforts

Two-thirds of the participants in a survey said that they would not work for an employer with a poor ESG record. Companies with strong sustainability programs attract star performers, especially among the younger generation of jobseekers.

Organizations with sustainable supply chains attract & retain a loyal workforce. It reduces recruitment costs & employee attrition.

Risk Mitigation

Working with third-party suppliers entails unavoidable risks. This includes operational, financial, regulatory non-compliance & cybersecurity-related vulnerabilities.

Sustainable supply chains require regular risk audits of suppliers, ensuring control measures are in place to identify & monitor threats.

Conclusion

The benefits of supply chain sustainability are enormous. For companies new to ESG strategies, the supply chain is an excellent place to start. A McKinsey report found that the most interesting opportunities for consumer businesses in sustainability performance lie with supply chains.

Sustainable supply chains are not only good for the planet & the people. It also drives business growth. In addition to the obvious ESG advantages of an ethical supply chain, it can create genuine value for an organization, its customers & suppliers.

At Gramener, our team of supply chain sustainability & consulting experts has delivered data science solutions to help logistics leaders reduce the turnaround time & enabled pharma giants to increase their golden batch yields.

We have also collaborated with Microsoft as its ISV Gold partner to help global non-profits combat climate change & save lives.

Contact us for custom built low code data and AI solutions for your business challenges and check out ESG and AI solutions built for our clients, including Fortune 500 companies. Book a free demo right now.