Managing smarter inventory is always challenging: too much stock consumes money, while too little results in lost sales.

It is quite challenging to meet cost and inventory goals since most businesses handle tasks in isolation, ignoring the complex interdependencies and impacts of changes across the system.

Artificial Intelligence is changing this situation and offering better ways to guess demand, reduce waste, and save money. By using AI tools, businesses can make their inventory processes more efficient, eco-friendly, and profitable than ever.

What is Inventory Optimization?

Inventory Management is basically about monitoring and controlling a business organization’s stock. It is a process that ensures that the right goods reach the right places at the right time. Inventory optimization is the core of inventory management. It guarantees optimal stock levels to meet customer demand, maximize profit, and minimize holding costs.

AI inventory management refers to using artificial intelligence tools to make inventory management better and more automatic. One of the primary areas of AI involvement in inventory optimization is enhancing efficiency, forecasting, and decision-making.

| Also Read – How to Future-Proof Warehouse Operations with Smart Inventory Management? |

Table of Contents

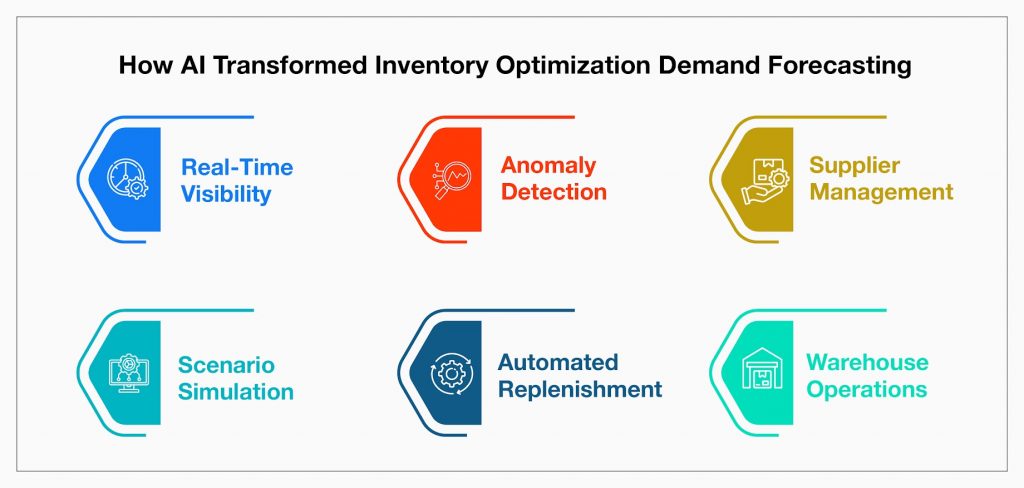

How AI Transformed Inventory Optimization

AI-enabled solutions are radically improving how businesses manage their inventory and transforming challenges into opportunities for growth. Machine learning has made the following areas key to inventory optimization.

- Demand Forecasting: AI directs businesses in forecasting customer demand accurately, thus helping in checking on overstocking or stockouts.

- Real-Time Visibility: AI provides real-time inventory monitoring, which aids in better decisions and faster responses.

- Anomaly Detection: AI identifies anomalies triggered by unexpected shortages or errors long before they lead to operational downtime.

- Supplier Management: Coordinates suppliers and evaluates their performance in chasing after reliable and efficient sourcing.

- Scenario Simulation: Organizations can utilize AI for simulating “what if” scenarios thus enhancing planning and risk management.

- Automated Replenishment: AI automatically restocks items in the warehouse, keeping inventory levels high without the need for people to do it.

- Warehouse Operations: AI improves picking, packing, and storing items in the warehouse, which increases efficiency.

Key Benefits of AI-Driven Inventory Optimization

In today’s fast-paced competition, AI Technology Eases Inventory Management by making it accurate, reducing costs and waste, and boosting efficiency. Companies can change stock levels and improve forecasting using AI to make operations run smoother for better results.

- Increased Accuracy: AI reduces forecast errors and improves data-informed decision-making.

- Costs Saved: AI helps cut operational expenses by optimizing stocks and avoiding waste.

- Increased Time-Efficiency: The work on mundane tasks frees employees from more value-added and higher-value activities.

- Improve Customer Satisfaction: AI guarantees customer friendliness by delivering products conveniently.

- Flexible Scalability: Inventory Control can adjust to the fluctuating requirements of a growing business as AI easily fits those requirements.

- Risk Mitigation: In-time detection of problems like stock-outs or excess inventory is mitigated very efficiently.

Challenges of Implementing AI in Inventory Management

Although AI provides powerful tools to optimize inventory, several challenges should be addressed for its successful implementation. Some technical, financial, and operational hurdles must be met for a business to take maximum advantage of AI.

- High Implementation Costs: Integration of AI systems often demands a high upfront investment in technology, infrastructure, and employee training. Small businesses may be priced out without the benefits to their bottom line.

- Data Quality and Consistency: For AI systems to function at their best, data must be of good quality and consistency. Low or inconsistent quality may result in bad predictions and wrong decisions.

- Complexity of Integration with Existing Systems: Legacy system integration can be challenging due to complex alteration and expert intervention, which can lead to issues of compatibility that slow down the transition.

- Limited Skilled Workforce: AI work requires specific operations and management skills. Many organizations cannot acquire the skills to work effectively with such advanced technologies.

- Resistance to Change: Employees and managers may resist implementing AI-driven solutions because they perceive a loss of jobs or intermittent processes. Such resistance is an obstacle to smooth deployment.

- Maintenance and Upgrade: AI needs to be constantly monitored, maintained, and updated in order to work properly. Thus, upgrading it calls for long-term resources that come with the operating burden.

Techniques for Optimizing Inventory with AI

A defined plan is a must to implement AI and align with the business goals. The following strategies make it integrate seamlessly and reap its benefits.

- Clear Objectives: Setting clear objectives, such as stockout reduction or better demand forecasting, leads to using AI.

- Focus on Data Quality: AI needs accurate data to give proper insights and optimize inventory.

- Cloud-Based Solutions: Clouds are flexible and scalable. Upfront costs to the organizations are reduced while improving growth.

- Phased Approach: Phase AI implementation controls risks and minimizes disruptions in daily operations.

- Train and Involve Employees: Engage the employees early and train them to ensure practical usage of AI tools.

- Monitor and Optimize Continuously: Regularly check up on AI performance and systems to update and maintain the effect to adapt to changes.

Future Trends in AI Inventory Optimization

Businesses will see improvements in machine learning, predictive analytics, and IoT integrations for future inventory optimization. Demand forecasts would improve, and real-time tracking of inventories through AI integration would be highly beneficial.

We at “Gramener”-A Straive company, help businesses leverage insights on AI-driven for more intelligent management of inventories and enhance efficiency while cutting costs to tailor-made solutions.

These technologies will help maintain more autonomous and agile systems, which will continue to give companies a competitive edge. So, let’s fix a meeting and make a better future with smarter inventory optimization today!